Skip to main content

Wet Processing

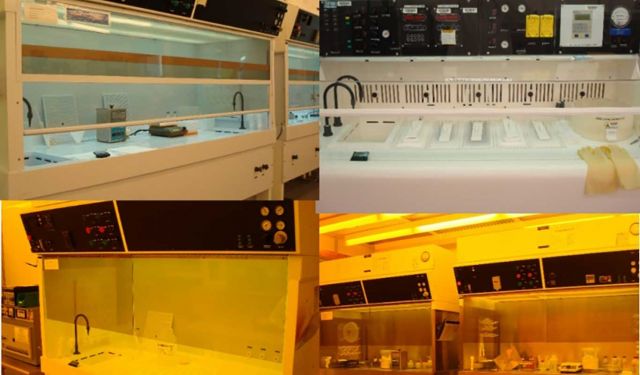

Solvent Bench #1:

- Designated for lift-off and general use

- Small bench-top ultrasonic bath

- Nitrogen guns

- Approved Chemicals: Acetone, isopropanol, toluene, NMP, and dimethyl sulfoxide

- Located in photolithography bay (yellow light)

Solvent Bench #2:

- Designated for resist stripping and general use

- Heated recirculating NMP bath with ultrasonic, can accommodate wafers up to 6"

- Hotplate stirrer

- Nitrogen guns

- Approved Chemicals: Acetone, isopropanol, toluene, NMP, and dimethyl sulfoxide

- Located in photolithography bay (yellow light)

Developer Bench:

- Designated for photoresist developing and rinsing of solvent soaked (isopropanol only) substrates.

- Single sink with goose neck faucet

- Nitrogen and DI water guns

- Approved Chemicals: AZ 400K developer, AZ 726 MIF developer and AZ developer

- Located in photolithography bay (yellow light)

Acid/Base Bench #1:

- Designated for perchloric acid cleaning process only

- Restricted use

Acid/Base Bench #2:

- Designated for general use; etching, cleaning, etc.

- Double sinks with goose neck faucets

- Nitrogen and DI water guns

- Hotplate

- Approved Chemicals: Sulfuric acid, nitric acid, hydrochloric acid, acetic acid, Nano-Strip, chromium etchant 1020, aluminum etchant Type A, hydrogen peroxide, and sodium hydroxide

Acid/HF Bench #3:

- Designated for RCA cleaning process, organics removal, and hydrofluoric acid use.

- Single sink with goose neck faucet

- Nitrogen and DI water guns

- 2 heated baths for Nano-Strip and H2O:HCl:H2O2 (5:1:1)

- 2 ambient baths for clean and dirty HF

- Cascading DI rinse bath with nitrogen bubbler

- All baths can handle wafers up to 8"

- Programmable spin dryer with multi size chuck that can handle 4, 6 & 8" wafers (non vacuum chuck type)