Nanofabrication Cluster

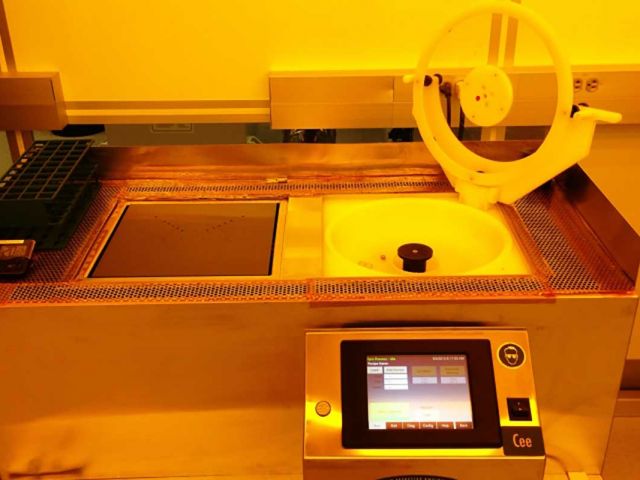

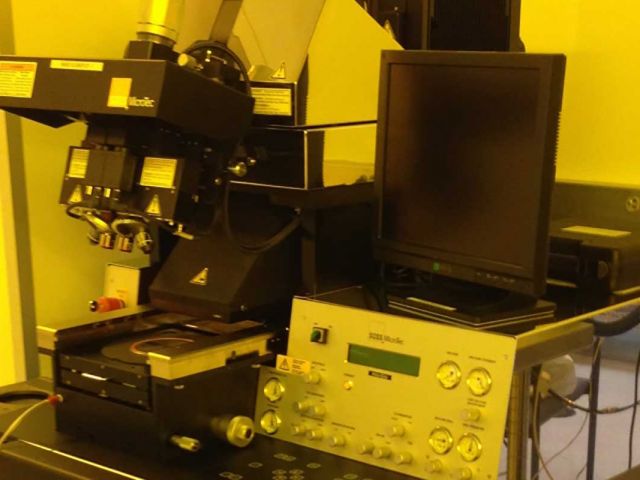

Lithography

A Class 100 yellow room for contact lithography and direct writing of photomasks and microfluidic molds. Tools include a Heidelberg direct-write laser lithography system, a Suss MicroTec MA/BA6 contact aligner, and support equipment for resist spin, bake, develop, ash, and inspection.

ECR Deposition

A solid-source electron cyclotron resonance (ECR) plasma deposition system that forms high-quality thin films. Films of various oxides and nitrides can be formed, as well as multi-layer films.

This tool was generously donated to UCSB by the JSW AFTY Corporation of Japan.

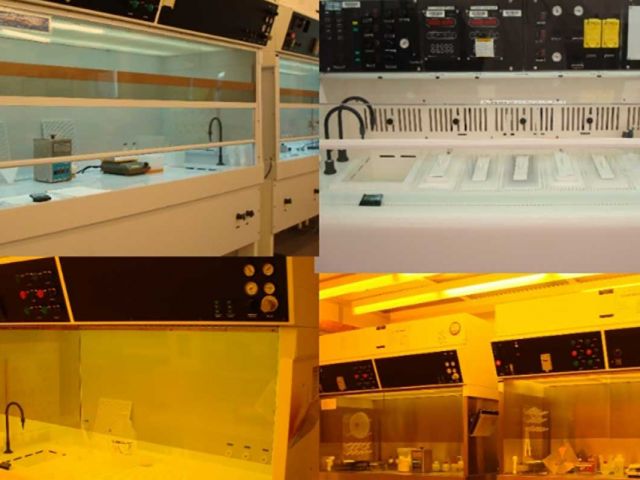

Wet Etch

Wet benches are available for solvent, acid, and base usage, including HF or perchloric acid cleaning.

How-to Information

- Steps to Access the Quantum Structures Facility

-

- Initiate an Access Request (see inset).

- Contact QSF staff to get trained on the instrument.

- Provide additional billing/access forms (to be requested from academic/industry users external to UCSB).

- Apply to CNSI for electronic door access to the facility.

- QSF Staff will add you to the FBS reservation system.

- Acknowledging Support

-

Please remember to acknowledge CNSI resources in scientific publications and presentations by including this statement:

“The authors acknowledge the use of the Quantum Structures Facility within the California NanoSystems Institute, supported by the University of California, Santa Barbara and the University of California, Office of the President.”

For work related to the Quantum Foundry also include:

"This work is supported by the National Science Foundation through Enabling Quantum Leap: Convergent Accelerated Discovery Foundries for Quantum Materials Science, Engineering and Information (Q-AMASE-i) award number DMR-1906325."