Machining Hub

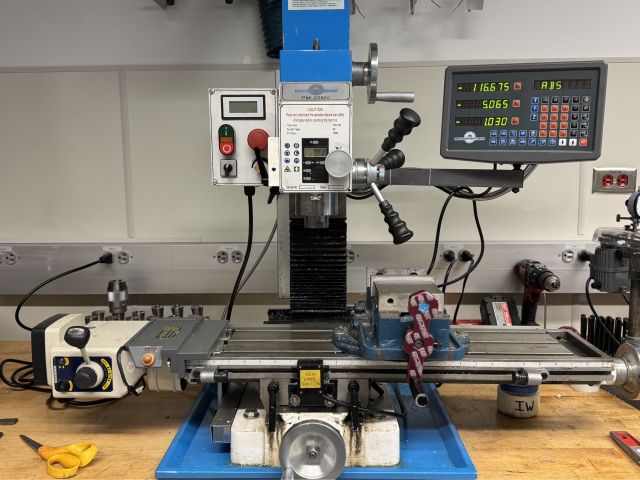

The Machining Hub, located in Elings 2442, is a galley-style shop with a variety of fabrication equipment. In addition to a full suite of traditional machining tools, the Machining Hub also features a spray booth for painting/coating, as well as a desktop waterjet cutter. This combination allows users to work with a wide range of materials including aluminum, titanium, spring steel, glass, carbon fiber, and rubber.

The Machining Hub is an extension of The Innovation Workshop, with the same access requirements and recharge procedure. The Machining Hub is open to all UCSB affiliates working on funded projects, as well as CNSI incubator companies and external companies.

How-to Information

- Steps to Access the Innovation Workshop

-

- Initiate an Access Request (see inset).

- Contact Innovation Workshop staff to get trained on the instrument. Completion of a new user orientation and safety briefing is required before obtaining card-key access to the CNSI Workshops. Tool-specific training is required for all tools and instruments in the lab

- All users must complete UCSB Environmental Health and Safety’s Fundamentals of Laboratory Safety course. The course is offered in person at the beginning of each quarter, and is also available on-line.

- Provide additional billing/access forms (to be requested from academic/industry users external to UCSB).

- Apply to CNSI for electronic door access to the facility.

- Innovation Workshop Staff will add you to the FBS reservation system

Complete instructions regarding access can be found here

- Acknowledging Support

-

Please remember to acknowledge CNSI resources in scientific publications and presentations by including this statement:

“The authors acknowledge the use of the Innovation Workshop within the California NanoSystems Institute, supported by the University of California, Santa Barbara and the University of California, Office of the President.”